Solid bamboo boards are a great combination of engineered flat boards and solid timber.

Solid bamboo boards are a great combination of engineered flat boards and solid timber.

Table of contents

If you are a joiner, kitchen or BIC manufacturer, furniture manufacturer, cabinetmaker, a mill worker or woodworking professional, we encourage you to take a good look at architectural bamboo boards.

Available as fit and finish ready bamboo timber in standard boards sizes.

Bamboo’s superior technical characteristics, competitive pricing compared to fit and finish ready timbers and it’s excellent green credentials offer compelling reasons to use bamboo boards in your next project.

We’re confident that once you have used Eco-Logic Bamboo boards;

- saving manufacturing time,

- reducing factory space requirements,

- optimizing labour utilization,

- minimizing machine time and requirements,

- and reducing consumable costs,

you’ll never look back.

What exactly is a “Solid Bamboo Board” and how do they fit in with other products?

Firstly, what are the other timber options?

Pressed boards

Engineered flat or pressed boards, is a general term for wood-based panels made from wood chips, shavings, particles, or fibers that are bonded together with a resin. They are also defined as Composite wood products

They are more commonly referred to as Chipboard, MDF, SupaWood, Melamine, etc. You will see composite wood in many products; furniture, wrap doors, kitchen carcasses, cabinets, shelving, countertops, built in cupboards, flooring and moldings.

There are a number of reasons one would use these composite wood products, including;

- Cheaper than solid timber.

- Available in standard sizes and thicknesses. This makes costing & manufacturing much easier.

- No preparation time required for planing, gluing & clamping as in solid timber.

- Lower wastage factor than solid timber.

There are also some drawbacks to using composite wood products;

- Easily damaged (beyond repair) by water exposure.

- Use high levels of cancer causing urea-formaldehyde based resins that off gas into the surrounding air.

- Lack structural strength.

Solid timber

Generally great to work with, can be used in a wide array of projects, structurally strong and can last life times. There are however some considerations with solid timber;

- Timber is expensive compared to pressed boards.

- Is not always readily available.

- Requires costly preparation work to ready the timber into boards or panels before the finished article can be assembled.

- High wastage factor compared to standard sized boards.

Bamboo Boards are a combination of the best of both these products.

- Bamboo boards are supplied in ready to use standard board sizes. No more preparation work (planing/gluing/clamping/cleaning, etc) before you can even start assembly of your product.

- Standard size boards have a lower wastage factor than solid timber.

- Structurally stable and with a higher tensile strength than cold pressed steel.

- Bamboo boards are the most moisture tolerant of woods.

- Formaldehyde emissions are lower than European standards requirements.

- Bamboo board derived finished products are costed cheaper than most solid timber finished products, especially once you’ve properly costed in all the preparation work and wastage.

So by switching to bamboo boards whenever you’d prefer to use solid timber (and usually end up compromising by using engineered flat boards). You will experience all these benefits plus be using a genuine eco-friendly product that is sourced from sustainable sources.

Climate tolerance of bamboo timber

Eco-Logic Bamboo boards are engineered for the wide variances in the sub-Saharan African climate. Anyone who has manufactured furniture in one climatic zone and shipped it to a client in another climatic zone knows the importance of well seasoned quality timber. Returns and repairs from across the country can really eat into profit margins.

One of our clients installed a vanity in Langstrand, Namibia – surrounded by the Namib Desert on three sides and the cold Atlantic waters on the fourth. This is a climatically harsh stretch of coast line between Walvis Bay and Swakopmund. The area came into recent fame because the Burning Shore Hotel, where Angelina Jolie and Brad Pitt stayed during the end of her pregnancy with Shiloh, is located in Langstrand.

This is what Joe Coetzee, the owner West Coast Joinery had to say about his Eco-Logic bamboo bathroom vanity, two years after it was installed:

I am very happy with my Eco-Logic Bamboo vanity, it is stable and perfect!

Bamboo Colours

All Eco-Logic Bamboo boards are available in the standard colours; lighter Natural or the darker Coffee (Carbonised) colours, as well as in the vertical grain, horizontal (distinctly bamboo) grain and the strand woven grain (wood like and exceptionally hard wearing).

In addition, bamboo boards stain wonderfully, so whatever colour or finish (stain, paint, wax, oil, polyurethane, etc) you desire can be applied to bamboo boards.

We have samples of painted and stained bamboo boards on the left, just to give you an idea of what’s possible.

We also have a number of clients using Eco-Logic Bamboo furniture boards – where the end product is painted, stained or veneered. Often one cannot tell that the product is manufactured from bamboo boards.

Why would they do this? Simple, our Eco-Logic Bamboo plywood boards are technically superior to other options. Also, in many cases more cost effective (especially when compared to the total cost of manufacturing the same item using solid woods). Add the fact that the product is made from a sustainable eco-friendly material and it’s a winner.

Machining and Cutting Bamboo

Bamboo’s consistent and predictable grain is another reason wood workers love working with the material. Any carpenter knows the frustration of machining an unpredictable timber and having to remove knots and fill in cracks and splits. All these extra steps have a cost associated with them. A cost of time and in material waste.

Here’s what Bill Pickering, a seasoned cabinet maker in Hilton, KZN had to say:

Working with Eco-Logic Bamboo boards is such a pleasure! It machines so well and predictably. No worrying about knots, splits and cracks.

Vertically cross laminated bamboo boards respond very well to machining; routers, CNC , laser cutting and water jet cutting. They can also be sanded to a very fine grit, creating a very luxurious finish.

Bamboo boards can be cut and sanded using conventional woodworking equipment, no special tooling is required. Gluing or mechanically fastening (screws) can be achieved using the same techniques, materials, hardware and fasteners commonly used with solid wood.

Bamboo job costing

Costing the preparation phase variables of a timber job is where all the financial risk sits – get it wrong and you could end up paying in on the job or loosing the job because the price is too high. Common challenges faced include;

- compensating for split, bowed, twisted, tapering and warped planks in a bundle,

- varying dimensions of the planks,

- compensating for planks that don’t machine well and have to be thrown away, necessitating starting from scratch if they were already glued up,

- timing of the labour and manufacturing costs of the individual components,

- buying extra material just to get the colour matching right.

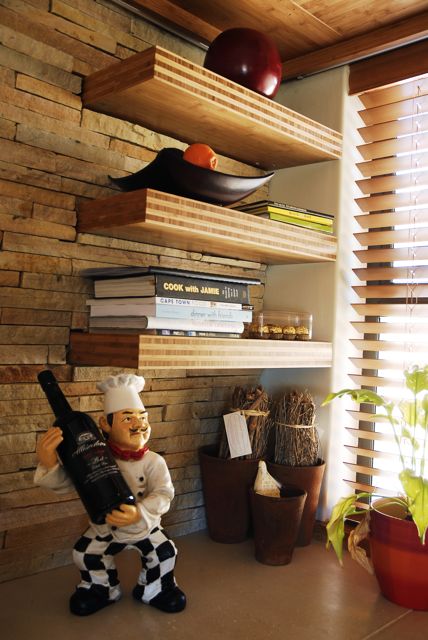

In contrast, bamboo boards are available in standard dimensions – ready for cutting, finishing and assembly. Simply calculate the optimal cut list for your job. Wastage is predictable and most manufacturers find other uses for the off-cuts, e.g. floated shelves, chopping boards, recipe books stands, you name it.

Bamboo wood stability and flatness

A special feature of Eco-Logic laminated bamboo boards, is their structural composition. All Eco-Logic Bamboo boards (besides the 5 mm boards) are specified with vertically cross laminated bamboo strips in the core layers to provide that additional rigidity and structural strength. This is often not the case with competing bamboo timber products.

The result of this extra stability?

- A structurally stable board that remains stable in the extremes of our Southern African climate.

- The boards can be used in a wider range of applications as they remain stable at greater dimensions. Always a challenge with solid timber and non-specified boards. Often stability issues are only solved by using more material to brace or using thicker planks or boards, raising the cost of the job.

Sign up for our “Working with bamboo timber boards” email tips series. It’s loaded with tips for those starting out.

Economic benefits of bamboo timber boards

With all the superior technical characteristics of bamboo, the competitive “total cost” benefits, Eco-logic Bamboo boards are an obvious and eco-friendly choice. They simply make economic sense in small and large scale manufacturing projects. Read what one of our customers had to say after switching from a bamboo board competitor to Eco-Logic Bamboo boards mid project …

On our recent project, M&B House in Cape Town, we were able to complete the cupboards and furniture for 3 to 4 rooms per day using Eco-Logic Bamboo boards compared to 1 room per day using another bamboo board suppliers product. We are very happy with the quality and time saved using Eco-Logic boards.Brian Spurdens. Owner of Mr. Bs Carpenters

Contact us for more info or bulk pricing on Eco-Logic Bamboo boards, plywood panels, counter tops and doors.

What are the common applications of bamboo boards?

Eco-Logic Bamboo Solid-2440*1220*3.2mm – Solid 3.2 mm cross laminated bamboo panel

The 3.2 mm multi-ply cross laminated bamboo plywood panel (bamboo plywood) is ideal for cladding, panel inserts, door inserts, cupboard backing or splash backs. Due to its longitudinal strength, it is also ideal for bending applications; e.g. skate board decks, surf boards & curved wall cladding.

Specifications | FAQ

Eco-Logic Bamboo Solid-2440*1220*16mm – Solid 16 mm cross laminated bamboo board

A popular and cost effective product for the Southern African market is the 16 mm bamboo board, especially the Strand Woven Boards. These bamboo boards are most often used for shelving, kitchen carcasses, risers, cupboard carcasses and doors, wall cladding and drawer fronts.

Specifications | FAQ

Eco-Logic Bamboo Solid-2440*1220*20mm – Solid 20 mm cross laminated bamboo board

The 20 mm bamboo boards are the most versatile thickness. With the 12 mm vertical cross laminated core, this bamboo board is suitable for a very wide range of applications; from shelving to cupboards, table tops to furniture frameworks, long length cupboard doors to door insets.

Specifications | FAQ

Eco-Logic Bamboo Solid-2440*1220*30mm – Solid 30 mm cross laminated bamboo board

The 30 mm bamboo boards are best suited in mixed media applications where other materials are 30 mm thick to compensate for their lack of tensile strength, e.g. granite, marble & pressed counter tops . They are thus very popular for kitchen counter tops, stair treads, breakfast nooks and solid internal doors.

Specifications | FAQ

Eco-Logic Bamboo Solid-2440*1220*40mm – Solid 40 mm cross laminated bamboo board

The 40 mm bamboo boards are often used for chunky furniture, doors (fire doors, external doors), butchers blocks, kitchen islands,shelving and staircases due to their exceptional rigidity and structural strength.

Specifications | FAQ

Bamboo Products

Solid Bamboo Boards & Plywood Panels Dimensions

| Dimensions | Construction | Surface Grain |

|---|---|---|

| 2,440 x 1,220 x 3.2 mm | 7 cross laminated layers | NH, NV, CH, CV |

| 2,440 x 1,220 x 5 mm | Single layer | NH, NV, CH, CV |

| 2,440 x 1,220 x 12.7 mm | 3 Vertically cross laminated layers 4-4.7-4 mm | NH, NV, CH, CV |

| 2,440 x 1,220 x 16 mm | 3 Vertically cross laminated layers 3.5-9-3.5 mm | NH, NV, CH, CV |

| 2,440 x 1,220 x 20 mm | 3 Vertically cross laminated layers 4-12-4 mm | NH, NV, CH, CV |

| 2,440 x 1,220 x 30 mm | 3 Vertically cross laminated layers 5-20-5 mm | NH, NV, CH, CV |

| 2,440 x 1,220 x 40 mm | 2 Vertical cross laminated layers and 3 plain pressed layers 4-6-20-6-4 mm | NH, NV, CH, CV |

Strand Woven Bamboo Boards Dimensions & Options

| Dimensions (millimeters) | Construction | Surface Grain | Comments & Common Applications |

|---|---|---|---|

| 2440 x 1220 x 5 mm | Single layer 5 mm | Natural (Oak like), Carbonized, Zebrano, Ebony | Great for cladding. ***Special handling requirements. |

| 2440 x 1220 x 12.7 mm | Vertically cross laminated solid bamboo core layer 4-4.7-4 mm | Natural (Oak like), Carbonized, Zebrano, Ebony | Cladding, drawer fronts and backing. |

| 2440 x 1220 x 16 mm | Vertically cross laminated core layer 3.5-9-3.5 mm | Natural (Oak like), Carbonized, Zebrano, Ebony | Most popular, cost effective and versatile. |

| 2440 x 1220 x 20 mm | Vertically cross laminated solid bamboo core layer 4-12-4 mm | Natural (Oak like), Carbonized, Zebrano, Ebony | Counter tops + applications with longer unsupported sections than the 16 mm board. |

| 2440 x 1220 x 30 mm | Vertically cross laminated solid bamboo core layer 5-20-5 mm | Natural (Oak like), Carbonized, Zebrano, Ebony | Counter tops, shelving, stair treads |

| 2440 x 1220 x 40 mm | Vertically cross laminated solid bamboo core layers 5-12.5-5-12.5-5 mm | Natural (Oak like), Carbonized | Stair treads, counter tops, butcher blocks, chunky furniture. |

| 2440 x 1220 x 40 mm | Vertically cross laminated solid bamboo core layers 5-12.5-5-12.5-5 mm | Zebrano, Ebony | Special construction using strand woven layer in the middle for stunning profile effect. Special order product. |

| NH = Natural (Colour), Horizontal (Surface Construction) |

| NV = Natural (Colour), Vertical (Surface Construction) |

| CH = Carbonised (Colour), Horizontal (Surface Construction) |

| CV = Carbonised (Colour), Vertical (Surface Construction) |

Contact us for more info or bulk pricing on Eco-Logic Bamboo boards, plywood panels, counter tops and doors.

Why not have a look at our bambooboard gallery to see how others have used our Eco-Logic Bamboo boards, or take a look at our frequently asked questions about bamboo …

If you are simply looking for a few bamboo boards, look up your local timber merchants.

Contact us for more info on our bulk pricing for large scale projects on Eco-Logic Bamboo boards, plywood panels, counter tops and doors.